Tank Solutions for Performance and Sustainability

CUSTOMIZED TANK SOLUTIONS

Maximum Performance

Our tanks are designed to meet specific customer requirements, delivering maximum performance, safety and sustainability.

Whether it’s stainless-steel tanks, carbon-steel tanks, cryotanks or pressure and vacuum vessels, we ensure a solution tailored to your needs.

We have extensive experience in delivering tanks to the energy sector, petrochemicals and other industrial segments, always focusing on optimizing operations and reducing costs through efficient and reliable solutions.

THE ENTIRE CHAIN

From Design to Assembly

Rodoverken manages the entire chain in the construction of tanks – from design and planning to construction and assembly.

We utilize our proven assembly methods for site-built tanks, giving us the advantage of fixed workstations and a controlled environment, independent of weather conditions.

This method ensures the best possible welding quality and a safe working environment, which is crucial for delivering tanks with the right quality and on time.

SECURITY THROUGHOUT THE PROCESS

Quality and Safety at Every Step

We prioritize quality and safety throughout the entire process, from design and material selection to construction and installation. Our work is certified according to the latest standards to ensure that each project meets or exceeds both our own and your requirements for safety and sustainability.

SAFE DRINKING WATER SUPPLY FOR THE FUTURE

Drinking Water Tank in Timanstorpet, Uddevalla

Rodoverken has constructed a new drinking water tank in Timanstorpet, Uddevalla. The tank, which is 24 meters wide and 7 meters high, is part of Västvatten’s initiative to secure the drinking water supply in the municipality for the next 100 years. By using stainless Duplex steel, the tank combines high strength with significant weight savings. Rodoverken was responsible for the entire construction, including insulation, scaffolding and coordination of subcontractors.

Drinking Water Tank

The tank has a capacity of 3,500 cubic meters.

Sustainable Material

The tank is made of stainless Duplex steel for long durability and weight savings.

Rodoverken’s Responsibilities

We were responsible for construction, insulation and coordination of subcontractors.

SAFE AND EFFICIENT ASSEMBLY

Assembly Methods

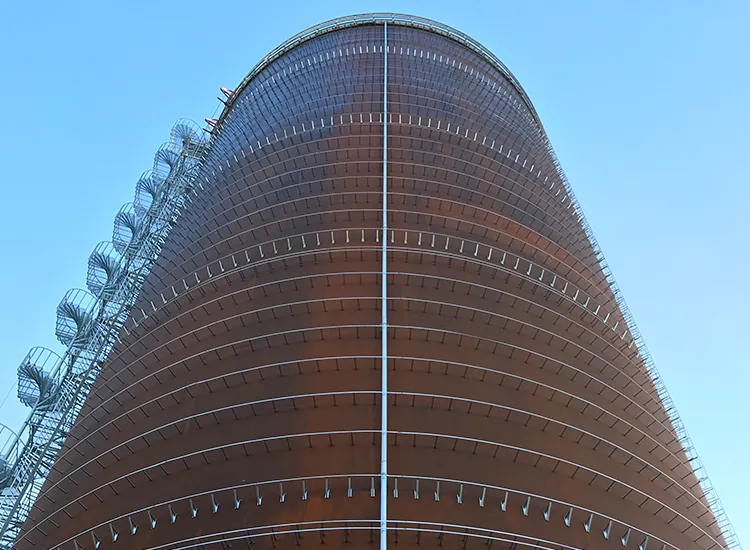

Spiral Method

Safe assembly regardless of weather conditions

- The tank is built from ground level or a low height for increased safety.

- Tank solutions for performance and sustainability

- Independent of weather, which enhances delivery reliability.

Hydraulic Jacks

Efficient step-by-step assembly

- The roof is built first and lifted incrementally for plate installation.

- Vertical welds are completed after each lift for stability.

- This provides a safe and controlled construction in multiple stages.

Electric Jacks

Optimal solution for stainless steel tanks

- The roof is lifted for the installation of the shell courses on stainless steel tanks.

- The upper part of the tank is rotated for precise horizontal welding.

- This ensures precision and quality at every workstation.

NO TRANSPORT

What are Site-Built Tanks?

Site-built tanks are custom-designed containers constructed directly at the installation site. This approach allows for the construction of very large tanks without the need for transportation, which is especially useful in projects where a high volume is required or where logistics pose a challenge. Site-built tanks are ideal for storing petroleum products, chemicals and other process media.

CUSTOMIZED FOR PROCESS REQUIREMENTS

Material Selection and Their Benefits

We utilize a variety of materials, such as stainless steel and carbon steel, depending on your needs and process requirements. Stainless steel is particularly suitable for corrosive environments, while carbon steel is economical and provides good strength. Pressure and vacuum vessels can be constructed from both stainless steel and carbon steel materials to meet specific process demands.

HIGHEST INDUSTRY STANDARD

Technical Expertise and Certifications

Rodoverken holds the necessary certifications to guarantee quality and safety in all projects. Our certifications include ISO 45001:2018 for occupational health and safety, ISO 9001:2015 for quality management, and SS-EN ISO 3834-2 for welding quality, ensuring that our products and work methods consistently meet the highest industry standards.

Frequently Asked Questions About Tanks

What types of tanks does Rodoverken build?

We build stainless steel and carbon steel tanks, cryogenic tanks, pressure and vacuum vessels, as well as tanks with floating roofs for various industries.

What does site-built tanks mean?

Site-built tanks are assembled directly at the installation site, allowing for large volumes and customized solutions.

What are the advantages of stainless-steel tanks?

Stainless steel tanks are corrosion-resistant and well-suited for environments with high hygiene and durability requirements.

Can the tanks be customized to specific needs?

Yes, we tailor each tank to the customer’s specific requirements, from design to material selection.

How is quality ensured in tank projects?

We use proven assembly methods and certified processes to ensure quality and safety at every step.

Contact Us Today

Rodoverken

AB

+46 10 470 70 00

info@rodoverken.se