RELIABLE PARTNER

Tank Maintenance

With our extensive experience and deep expertise in tank maintenance and repairs, Rodoverken is a reliable partner for your projects. We guarantee a safe and straightforward journey for our customers, where quality and timely delivery are always our top priorities.

At Rodoverken, we work in a project-driven manner throughout the entire process of tank maintenance and repairs. From the initial contact to the completion of the work, we manage each project with clear planning and structured project management.

We collaborate closely with our customers to understand their specific needs and tailor our solutions accordingly, ensuring a smooth and reliable journey from start to finish.

FOR ALL MAINTENANCE NEEDS

Our Services

Roof Repairs

We repair or replace roofs to ensure tightness.

Replacement of Pressurized Parts

We replace parts such as jackets and bottoms to extend the tank’s lifespan.

Emergency Repairs

We quickly address failed tanks to minimize downtime.

Inspection and Maintenance

We offer regular inspections to prevent future issues.

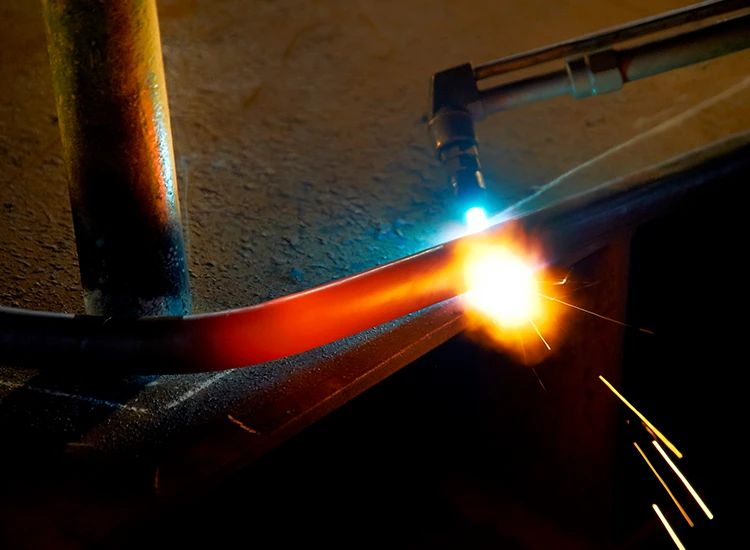

Welding Services

We perform specialized welding work for the highest quality.

Floating Roof Repairs

We maintain floating roofs for petrochemical tanks.

BIG OR SMALL

Maintenance and Repairs for Your Needs

We tailor our maintenance and repair services to each customer’s specific needs and the scope of the project.

Whether it’s a minor repair, parts replacement, or extensive maintenance, we customize the solution to meet your requirements.

By working closely with our customers, we ensure that every action is carried out efficiently and with a focus on quality and safety, so your tanks and systems remain in the best possible condition for continued operation.

A RELIABLE PARTNER

Long Experience in Tank Projects

When you choose Rodoverken, you gain a trustworthy partner with decades of experience in tank construction, maintenance, and repairs.

Each project is handled with high precision from planning and design to execution and follow-up.

With experience across various industries—such as energy, petrochemicals, water, and process media—we ensure that your specific needs are met in the best possible way.

MAINTENANCE PROJECT

Efficient Shell Replacement on a Pulp Storage Tower

In 2019, Rodoverken carried out a comprehensive maintenance project involving the replacement of the shell on the upper part of a pulp storage tower. The new shell has a diameter of 16 meters and a height of 30 meters. The new section was installed during the factory’s planned production shutdown.

One of the key aspects of the project was the prefabricated top, which allowed for smooth and efficient installation during the downtime. Rodoverken utilized the SIM method during the prefabrication for both welding and assembly, contributing to high precision and short lead times.

The project was completed in a short time, thanks to careful planning and coordination, and was executed smoothly during the production stoppage.

Project Scope:

Scaffolding Work

Erecting necessary scaffolding to enable work at height.

Crane Operations

The prefabricated shell section, weighing 70 tons, was lifted into place using a 500-ton crane.

Dismantling and Assembly

The deformed shell was dismantled and replaced, followed by careful welding and joining of the new sections.

Insulation

After assembly and welding, new insulation was applied to ensure optimal performance.

Frequently Asked Questions About Maintenance

What types of maintenance does Rodoverken offer?

We offer everything from inspections and minor repairs to complete replacements of tank components.

How can I tell when my tank needs maintenance?

Regular inspections help identify needs before problems arise.

How long does a typical repair take?

The duration varies depending on the extent of the damage, but we always work to minimize downtime.

Do you also perform emergency repairs?

Yes, we provide quick responses to address urgent issues and minimize production losses.

Contact Us Today

Rodoverken

AB

+46 10 470 70 00

info@rodoverken.se