COMPLETE SOLUTION

Assembly Methods

At Rodoverken, we offer complete delivery of tanks, including calculation, design, assembly and insulation. We utilize three assembly methods, which are tailored to your specific needs and conditions to ensure the best possible results. Here is an overview of our methods and their advantages for you as a customer.

UNIQUE TO RODOVERKEN

Spiral Method

With this method, we construct the tank from ground level or a low height, providing a safer working environment and reducing the risk of disruptions. Fixed workstations ensure high quality throughout the entire process, regardless of weather conditions. It is an efficient and flexible method that ensures both time and quality in the delivery.

- Safe working environment from ground level

- Independent of weather conditions

- Unique method developed by Rodoverken

WORK IN STAGES

Hydraulic Jack

Here, the tank’s roof is built first, which is then lifted gradually while the shell courses are installed and welded. This method provides stability and safety by allowing the work to be done in stages, making it easy to adapt and control each step.

- Stable and controlled process

- Efficient step-by-step assembly

- High precision and safety

PRECISE HORIZONTAL WELDING

Electric Power Jack

This method is used for stainless steel tanks and is based on the same principle as the hydraulic jack. The upper part of the tank is gradually lifted, and the shell courses are installed from below. The tank is rotated for precise vertical and horizontal welding, ensuring smooth and accurate assembly.

- Optimal for stainless steel tanks

- Exact horizontal welding

- Safe and controlled assembly

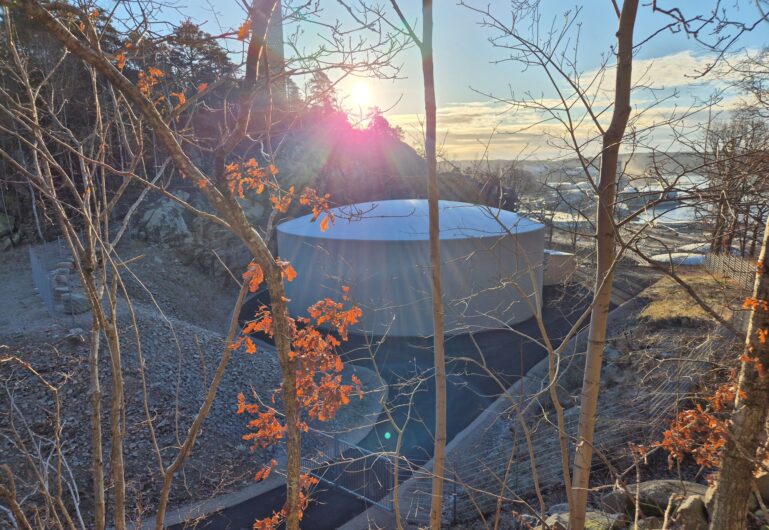

Reference Projects

Contact Us Today

Rodoverken

AB

+46 10 470 70 00

info@rodoverken.se